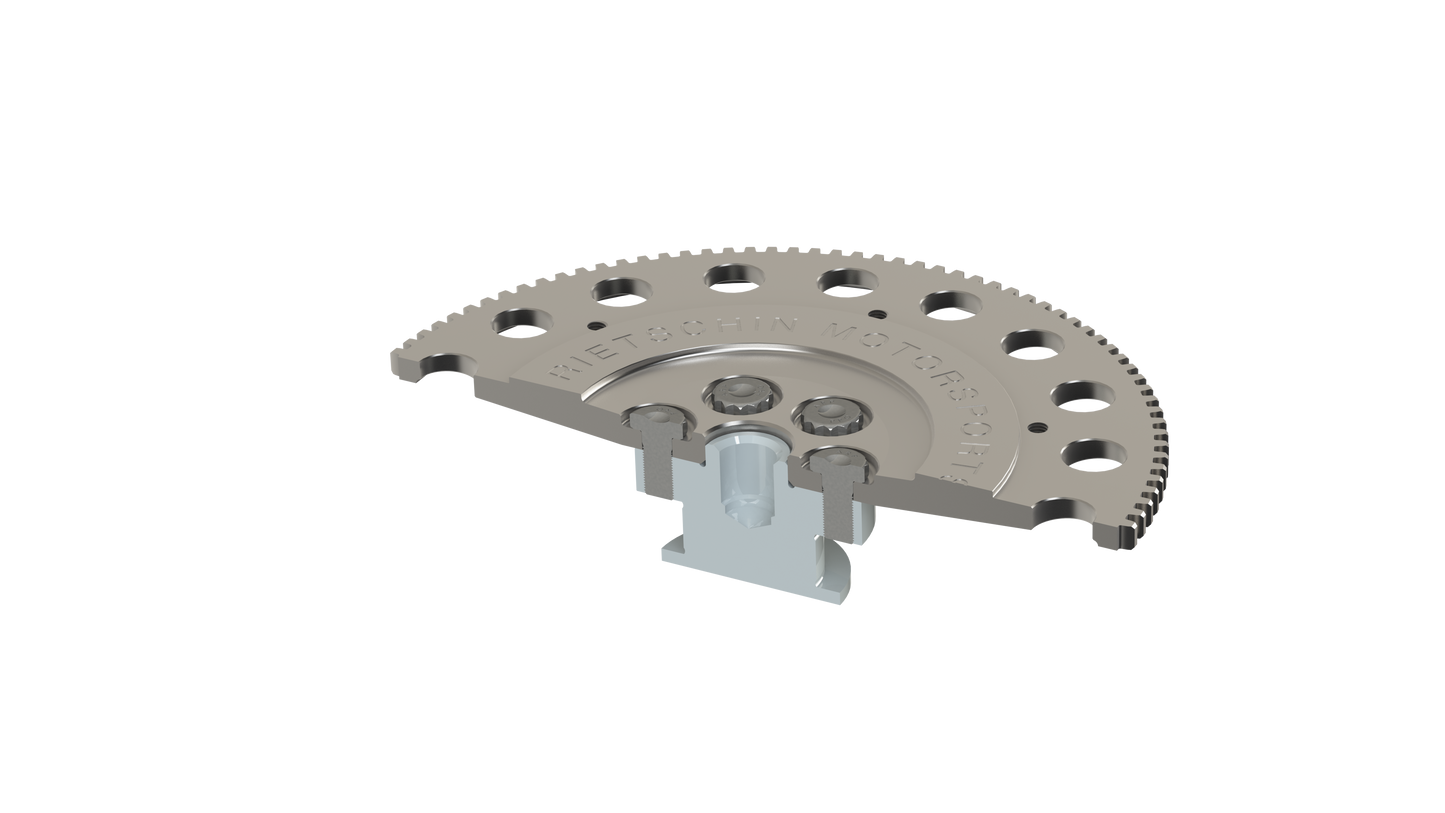

RIETSCHIN MOTORSPORT, LLC

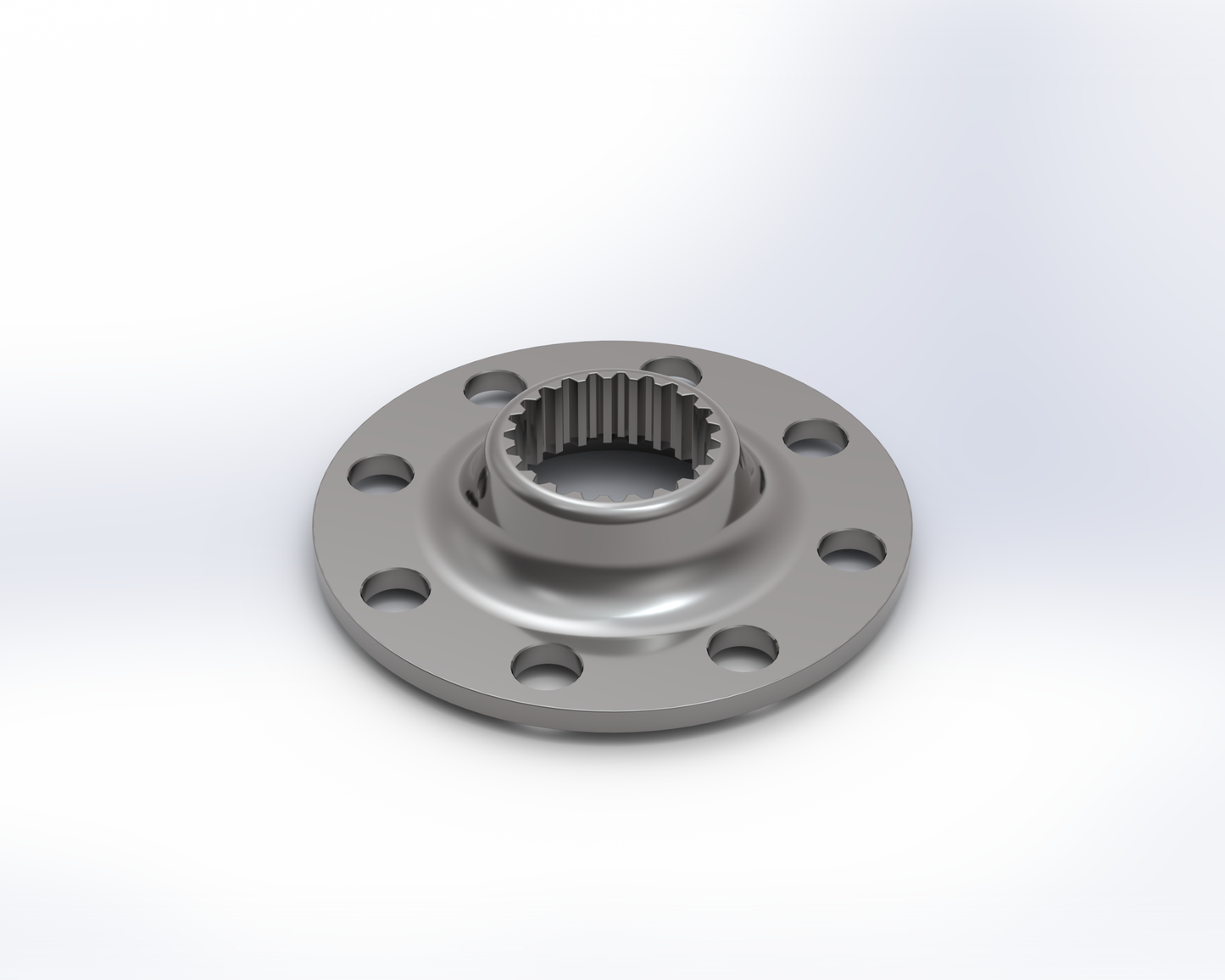

Focus RS Triple-Plate Low Inertia Racing Clutch + Flywheel Kit

Focus RS Triple-Plate Low Inertia Racing Clutch + Flywheel Kit

Couldn't load pickup availability

Lightweight 184mm (7.25") triple-plate racing clutch and flywheel kit. Fits Ford Focus RS 2016-2018 as well as Ford Focus ST with 2.0L EcoBoost Engine.

- Low inertia high rigidity hard anodized aluminum cover.

- Chromoly pressure and floater plates.

- Hardened wear pads, reduce pressure plate release stiction.

- High quality engineered drive hubs with proper mating to input shaft spline, reducing idle rattling noises to a reasonable level.

- Triple 6-pad cerametallic driven plates with high fatigue resistance.

- Fully rebuildable: pressure plates, floating plates and driven plates available separately.

- Clutch fixings included.

- Choice of torque capacities. Numbers are minimums over the service life of the clutch (up to 0.8mm total wear)

- 560 lbft (772Nm)

- 654 lbft (886 Nm) <- recommended.

- 821 lbft (1113 Nm)

- 995 lbft (1295 Nm)

- Supplied new Ford clutch release bearing with custom adapter ring. Tested with 654 lbft (886 Nm) variant.

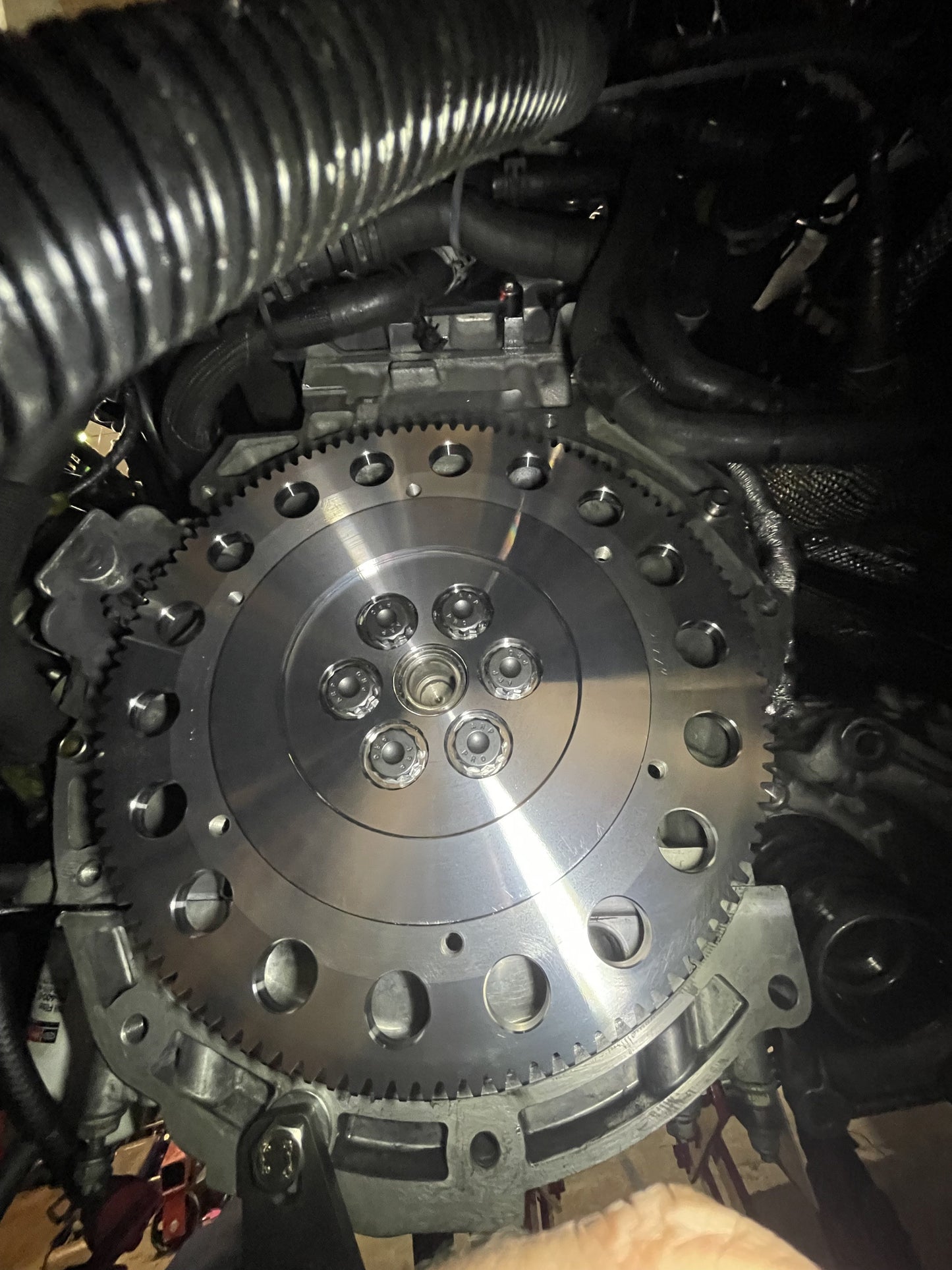

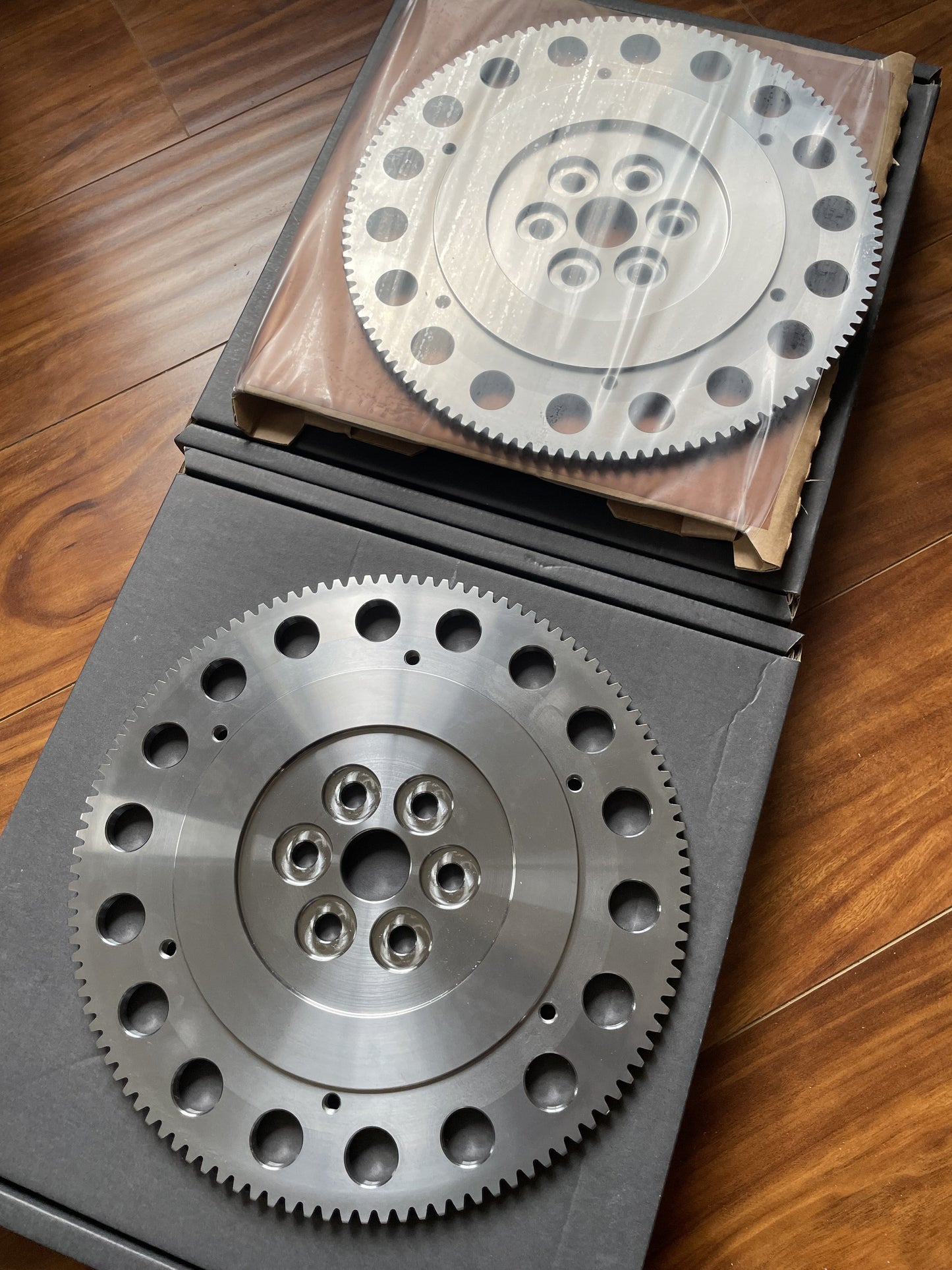

- Chromoly, monobloc CNC-machined flywheel with integrated starter ring gear. Hardness suitable for use with cerametallic pads.

- Custom disc hubs designed to maximize spline engagement.

- Precision machined for perfect mating and exact centering on the crankshaft.

- Balanced during the manufacture.

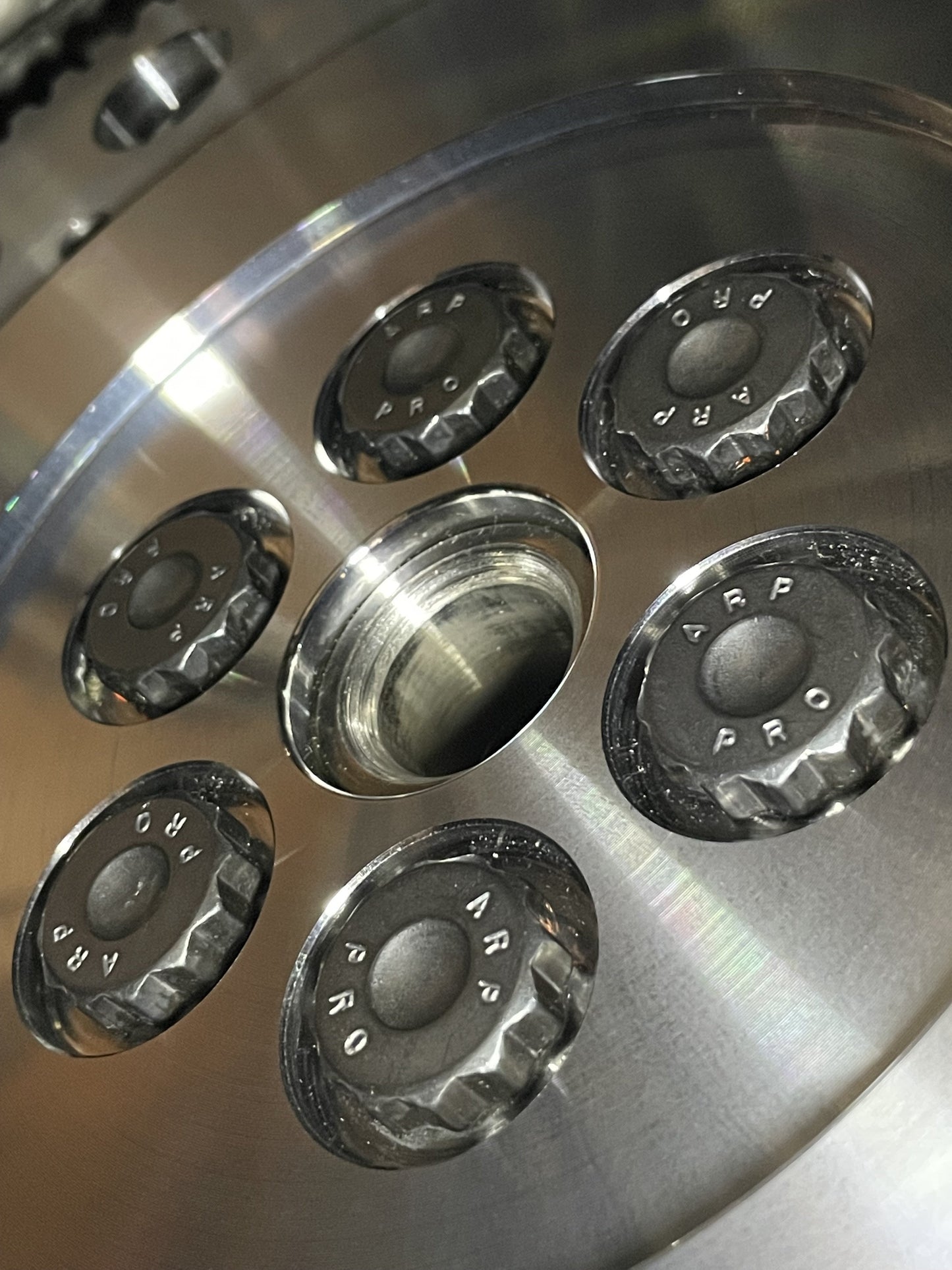

- Designed for ARP 251-2802 flywheel bolt kit.

- Can be resurfaced at least once by most machine shops. Step 2.54mm (1/10”)

- Kit includes:

- New racing clutch complete with pressure plates, driven plates, and fixtures. ~6.6kg (~14.55lb) total.

- New lightweight billet steel motorsport flywheel ~4.4kg (~9.7lb)

- New genuine Ford DG9Z7A564C release bearing with custom adapter ring.

- New genuine ARP 251-2802 high-tensile reusable M12x1.0 bolt kit.

- 7g (¼oz) CMD #3 anti-scoring assembly grease for use with ARP bolts.

- Printed installation guide.

- COBB “Stage 0” map with our recommended modifications to the calibration (idle speed, cranking ignition timing, misfire detection, rev hang delete, take-off settings and more) that your tuner can selectively import as needed to customize your setup.

- Precision engineered, precision machined, durable and perfect fit.

- Total weight reduction compared to stock: approx. -7.3kg (-16.1lbs) rotating.

- Lower inertia for fast engine response (due to smaller diameter and low mass)

- The clutch is an off-the-shelf precision-engineered race clutch manufactured by a racing part specialist in the UK.

- The flywheel and package were designed and tested in Washington State, U.S.A

The flywheel has an integrated starter ring gear machined straight into the same piece of metal. This increases reliability compared to other aftermarket offerings: a common issue of aftermarket flywheels is that the hardness of the core material is not enough to be used as starter gear and a separate hardened metal ring gear is affixed. Under extreme use and abuse, the core material expands due to heat and cracks the affixed ring gear. The alloy flywheels also sport a steel friction disc held by small screws which has a very hard time staying flat after a few heat cycles, resulting in reduced torque capacity, terrible (unpredictable) engagement characteristics and increased wear. Our single-part rigid design completely avoids those issue.

Our all-steel flywheel is lighter than most aluminum flywheels on the market and has lightening holes near the circumference, where it counts to reduce inertia. Combined with the small-diameter clutch, the entire package (flywheel and complete clutch with all plates and clutch bolts) weights at just 10kg total (22lb) which is about as low as reasonable for vehicles that may occasionally be driven on the street. That being said...

Disclaimer: Racing clutches are meant for racing use. They withstand extreme abuse in racing environments and deliver improved performance through weight reduction, inertia reduction, faster acceleration in short gears, quicker gear changes, improved heat resistance, and much increased torque capacity. However, their unmatched performance comes at a price: their service life is much shorter than an OEM clutch and their brutal engagement characteristics makes them poorly suited for street use and daily driving, especially with repeated use in start-stop traffic. Metallic clutches also require more skills and finesse from the driver than any other clutches.

Recommendations:

- For ultimate performance and fastest gear changes we recommend using uprated synchros rings. Carbon synchro ring kits are available separately from specialists.

- For additional inertia and weight reductions we recommend pairing this race clutch kit with one of our lightweight crankshaft pulley kits for up to 1.96kg (4.33lbs) additional rotating weight reduction.

- For best control and pedal feel, we recommend using a direct braided hydraulic line going straight from the master cylinder to the hydraulic release bearing.

- If building the engine, consider a lightened Callies or Arrow Precision crankshaft for another 4.5kg (9lb) rotating weight reduction. Make sure you balance your rods and piston assemblies to within a gram across all four cylinders and the engine will run like a Rolex.

- Removing the balance countershaft assembly and screws saves another 5.2kg (11.5lb) for up to approximately 19kg (42lb) weight reduction in total so far (clutch, pulleys, crankshaft, balance shaft) - most of which rotating. The stopwatch will certainly notice that!

- For track builds the AC compressor and main pipes can easily be removed for another 6.8kg (14.8lbs) weight saving, bringing the total reduction near 26kg (57lbs) - More if you remove the AC condenser. Combined with a Li-Ion battery you can remove close to 50kg (110lbs) from the engine bay!

- If you have a custom tune then your tuner can tweak several settings to your liking. We supply a sample map (COBB Focus RS 2016+ Stage 0) with the modified settings that works for us and that your tuner can use as inspiration or selectively import into your custom map to further refine your setup.

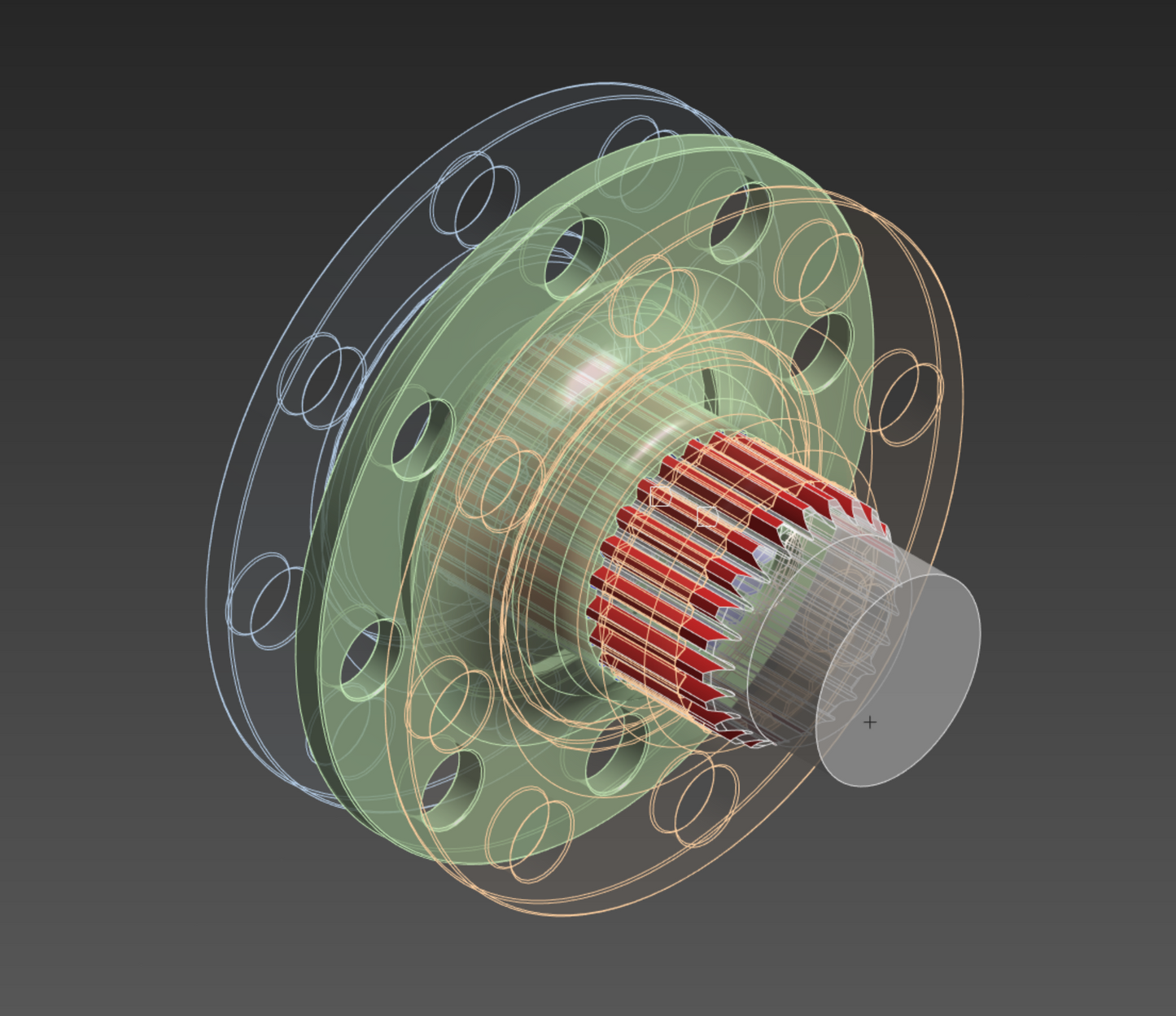

Pictures shows computer renderings of the flywheel, a screenshot of a high-RPM stress study computer simulation, as well as pictures of the actual kit we used for in-car testing. ARP flywheel bolts included. Production parts will be available in Spring 2024.

Share